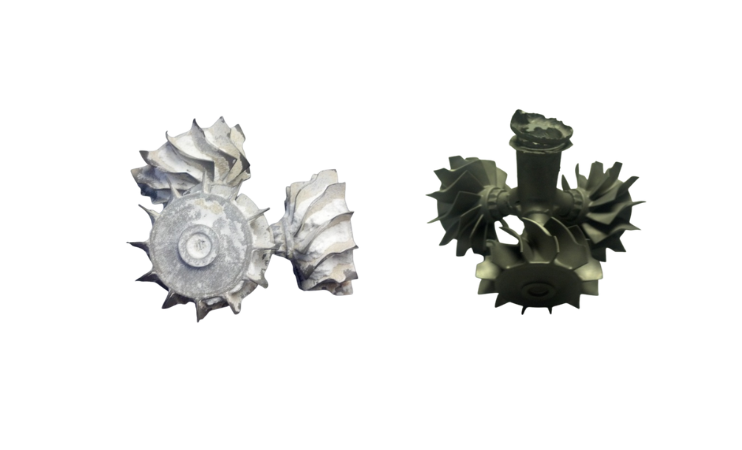

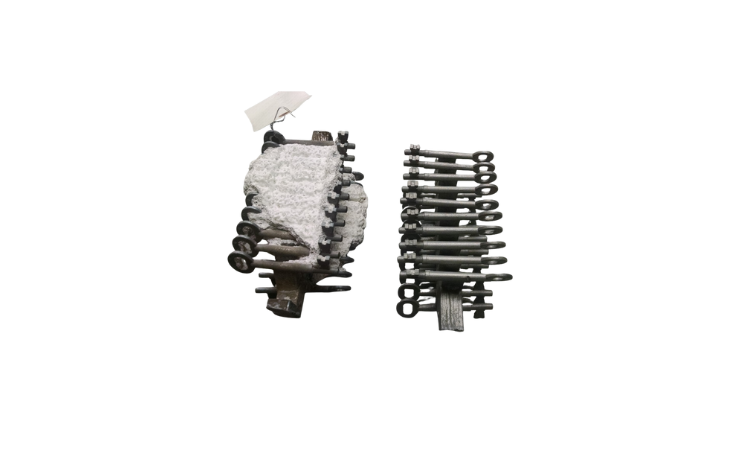

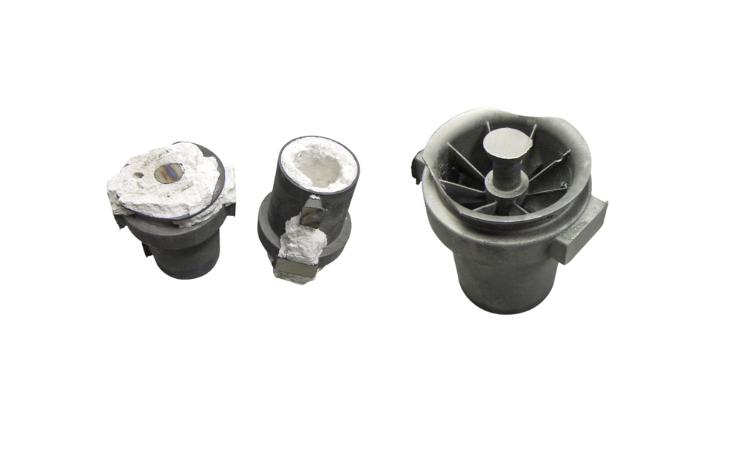

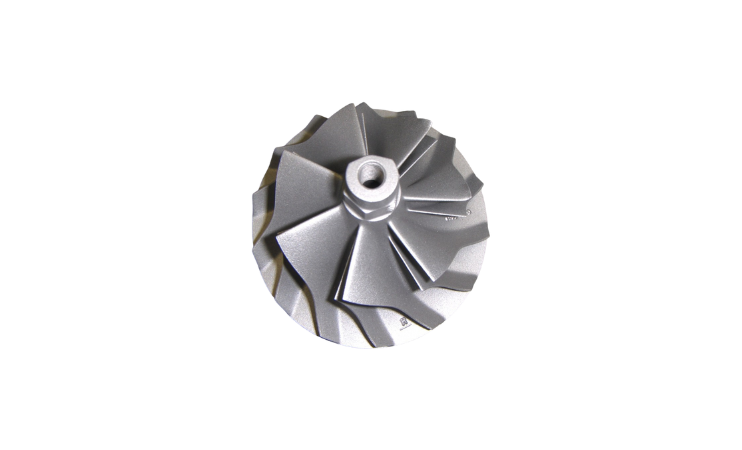

Investment casting, also known as the “lost wax” method of metal casting, it is used for producing intricate shapes. These types of castings are not only for the aerospace industry but also for many other industries, often replacing fabrications. Investment castings are produced by making a ceramic shell mold and pouring molten steel into that mold. Once the castings have cooled, the task of removing the shell from the casting is started, first by a pneumatic hammer to break the shell and then various methods are employed to remove the balance of the shell. Because these castings are often delicate, traditional shot blasting can be too aggressive, leaving the surface of the casting damaged by the impacts of the shot. So, another form of cleaning is employed, submersing the castings in a caustic bath (Colene Treatment to dissolve the remaining shell). When you put the castings & shell into this Colene bath, the solution rapidly becomes contaminated with shell. The more ceramic that goes into the solution, the more rapidly the solution becomes fouled. An alternative to the excessive use of this caustic treatment is to first blast the castings with NU-SOFT Shot. Because NU-SOFT Shot is softer than the castings being blasted, the castings can be blasted for longer blast cycle times, without the worry of damaging the castings but still, removing more shell material. This will reduce the dependency on the caustic treatment and in some cases, will eliminate the need for the caustic, all together.

- Industry/Application: Aerospace, industrial metal casting

- Challenge: Remove ceramic shell without damaging intricate steel castings

- NU-SOFT Solution: Pre-blast with NU-SOFT Shot before caustic bath

- Benefits: Reduces chemical use, lowers contamination, preserves part integrity

- Media Used: NU-SOFT Shot