Case Studies

Explore real-world applications and learn how to leverage advanced abrasive media for precision surface preparation. From the durable performance of grit and shot, read case studies over blasting media like V-Blast and R-Blast Brown Fused Aluminum Oxide, Nu-Soft Steel Shot, Zero Valent Iron, and more. These resources are designed to help customers choose the right materials for performance, efficiency, and environmental responsibility.

NU-SOFT

Auto Parts Rebuilding

In the auto parts rebuilding industry, it is necessary to blast clean parts (castings) that have been machined, but this will damage the machined surfaces and make it necessary to re-machine those surfaces. But often when these parts are re-machined, it changes pre-designed tolerances, which is unacceptable. Engine blocks and...

Read More

Aluminum Extruders

Firms extruding aluminum through an iron or steel die need to clean those dies periodically and they have found that any abrasive media that is too aggressive will change the dimensions of the openings on the dies, thus changing the dimensions of the aluminum extrusions being produced. NU-SOFT Shot is...

Read More

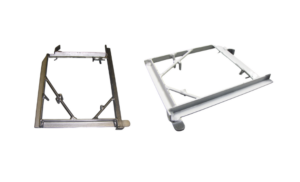

Paint Fixtures

Automotive assembly plants and large suppliers will send sheet metal parts through automated paint booths, hanging each component using paint hooks or fabricated fixtures. After repeated use, the paint build-up on these fixtures or hooks needs to be removed. Cleaning can be accomplished by several methods. Chemical stripping is both...

Read More

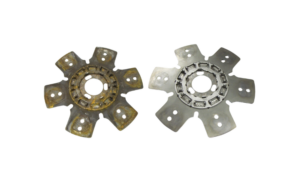

Powered Metal Gears

Industry/Application: Automotive gears Challenge: Remove sharp edges without damaging parts NU-SOFT Solution: Blast cleaned safely without altering surface Benefits: No texture, sharp edges removed effectively Media Used: NU-SOFT Shot

Read More

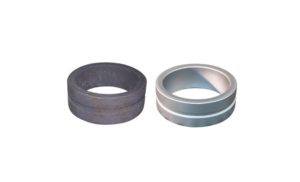

Disc Brake Calipers

Firms that rebuild (remanufacture) automotive disc brake calipers have a problem with damage to the tapped (threaded) holes after shot blasting. In most cases, these holes are plugged with plastic plugs prior to blasting and, hopefully, these plugs will remain in the holes until manually removed after the blasting cycle....

Read More

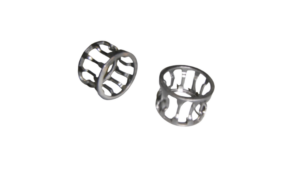

Bearing Cages

In roller bearings, there are thin stamped metal cages which hold the roller bearings in place. These pieces are stamped, rolled, and welded to form a round shape. Before these pieces can be used, the sharp edges must be deburred so they do not scratch the roller bearings. Vibratory finishing...

Read More

Compressor Rebuilders

Companies rebuilding commercial air compressors or air conditioner compressors need to clean the components during the rebuild process. These compressors are very similar to internal combustion engines but without any ignition of fuel. So, the internal surfaces need to be cleaned without damaging the cylinder bores, machines surfaces and threaded...

Read More

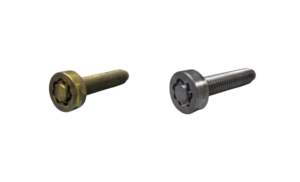

Fastener Manufacturers

Fasteners (nuts & bolts, etc.) that are produced for the automotive or similar industries are coated with some type of protectant, mainly for cosmetic purposes. Frequently, there are rejects from the coating process. How do you remove the coating without damaging the threads? Frequently, firms use a dipping process to...

Read More

Aluminum Die Casting

Aluminum die casting is done by injecting molten aluminum into a mold made of a series of cast iron dies. When these dies are new, the fit is great and there is little or no aluminum that escapes from the joints. As the dies wear, ore and more aluminum escapes...

Read More

Truck Transmission Building

On large commercial truck transmissions, there are machined surfaces on power take-off housings and side covers. When cleaning these housings, if they are blasted with steel shot, these surfaces need to be re-machined, or a thicker gasket must be used to assure proper meshing of the gears. Blasting with NU-SOFT...

Read More

Investment Casting

Investment casting, also known as the “lost wax” method of metal casting, it is used for producing intricate shapes. These types of castings are not only for the aerospace industry but also for many other industries, often replacing fabrications. Investment castings are produced by making a ceramic shell mold and...

Read More

Mold Cleaning

Cleaning iron or steel molds used in the glass & rubber industries and in some permanent mold aluminum foundries. These molds can cost many thousands of dollars to produce and, in use, are coated with a mold release agent to allow easy separation of the part from the mold. Over...

Read MoreFill out the contact form below

A MEMBER OF OUR TEAM will get back to you as soon as possible. We look forward to working with you!