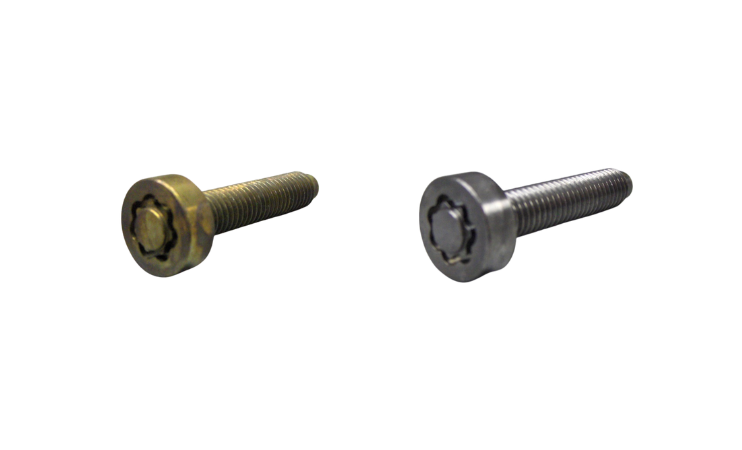

Fasteners (nuts & bolts, etc.) that are produced for the automotive or similar industries are coated with some type of protectant, mainly for cosmetic purposes. Frequently, there are rejects from the coating process. How do you remove the coating without damaging the threads? Frequently, firms use a dipping process to remove the coating prior to re-coating. This is often a slow process that involves disposing of the chemical strippers. Now, these fasteners can be blast cleaned using NU-SOFT Shot without worrying about thread damage. Abrasive blasting is both cheaper and faster.

- Industry/Application: Automotive

- Challenge: Coating removal damaged threads

- NU-SOFT Solution: Blast cleaned without chemical stripping

- Benefits: Fast, non-destructive, cost-effective

- Media Used: NU-SOFT Shot