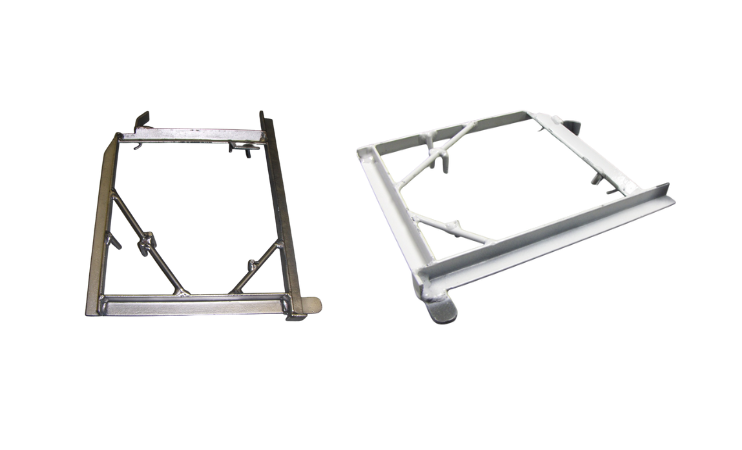

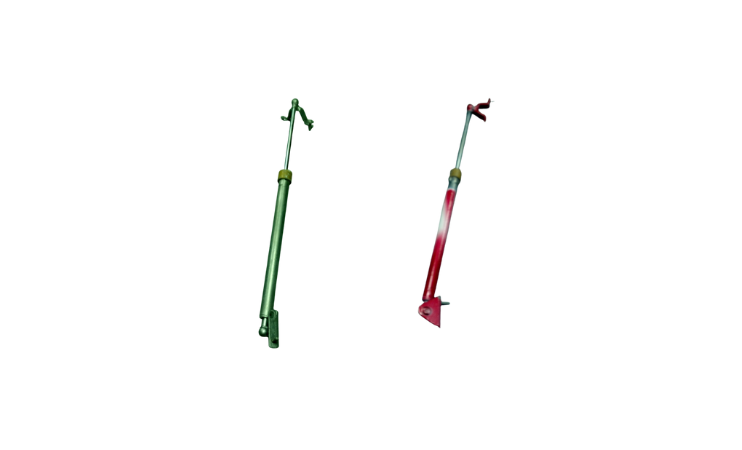

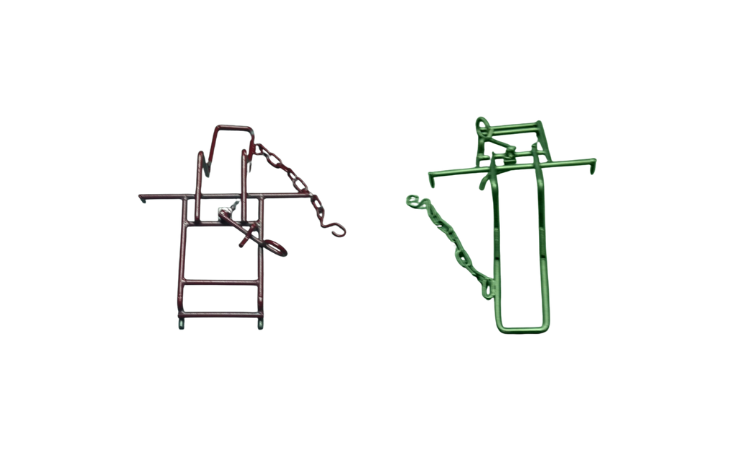

Automotive assembly plants and large suppliers will send sheet metal parts through automated paint booths, hanging each component using paint hooks or fabricated fixtures. After repeated use, the paint build-up on these fixtures or hooks needs to be removed. Cleaning can be accomplished by several methods. Chemical stripping is both expensive and slow and shot blasting can cause damage from something called “peen forming,” where the parts bend from the impact of the shot. Some choose to blast with zinc shot because it is soft and will not peen form or bend the fixtures. However, the cost of zinc shot is high, making it cost prohibitive. Blasting with NU-SOFT will save on media costs and will remove the paint build-up more quickly.

- Industry/Application: Automotive

- Challenge: Paint buildup removal deformed or bent fixtures

- NU-SOFT Solution: Used NU-SOFT instead of zinc shot

- Benefits: Cost-effective, faster cleaning, no peening

- Media Used: NU-SOFT Shot